Aspheres & Freeform Optics. High Image Quality and Weight Reduction.

We develop and produce customer-specific aspherical lenses and freeform surfaces in small batches.

Aspheres are used in many optical systems since they provide precise light guidance as well as better performance with less optical elements. This allows for compact designs with less losses and lower weights, which is especially important for mobile devices.

We offer concave or convex aspheres with diameters of 12 to 350 mm with the highest accuracies and in various materials.

Specifications

Materials

| Materials | Optical glass, quartz glass, Zerodur®, crystalline materials, metals |

|---|

Dimensions and Forms

| Diameter (± tolerance) | 12–350 mm (±0.03) |

|---|---|

| Center thickness tolerance | ±0.01 mm |

| Free aperture | up to 100 % of ∅ |

| Local radius of curvature concave | > 10 mm |

| Departure from best-fit-sphere | up to a few millimeters |

Surface Form Error

| Sagitta deviation (SAG, "Power") | ±0.3 µm |

|---|---|

| Irregularity (IRR, "PV") | 0.1 µm |

| Rotational invariant irregularity (RSI) | 0.05 µm |

| RMS irregularity (RMSi) | 0.02 µm |

| Slope error, 1 mm integration length | 0.06 mrad |

Centration

| Edge thickness difference | 3 µm |

|---|---|

| Decenter asphere to edge | 3 µm |

Surface

| Surface roughness Rq | 1 nm |

|---|---|

| Surface imperfection tolerances | 3 x 0.063 (ISO 10110-7) 20–10 (acc. to MIL–Scratch/Dig) |

| Coatings (UV, DUV, VIS, NIR, IR) | AR, BBAR, HR mirrors, customer-specific coating designs |

Measurement Technique

| Surface form error interferometric |

Zygo Verifire Asphere, CGH Technologies, |

|---|---|

| Surface form error tactile | MarSurf LD 260 Aspheric, Form Talysurf PGI 1000 |

| Surface roughness | Zygo NewView 700 white light interferometer |

In addition we have extensive finishing competence with regard to the production of high-precise freeform surfaces. Freeforms can be produced deterministically from planar and spherical areas with a deviation of up to 100 um from the best-fit area. The surface accuracy that can be achieved and measurability will be determined for each solution.

We would be pleased to discuss your requirements with you.

Innovative measurement techniques

Manufacturing high-precise aspheres is closely related to nanometer-exact characterization of the surfaces processed. We measure the entire surface of the aspheres produced and use, depending on the application, the Verifire Asphere asphere interferometer, in-house designated computer-generated holograms or a newly developed tilted-wave interferometer in order to do so.

Correction of aspherical components

Speed and flexibility

We flexibly adapt to your individual requests, have a very fast development process and employ proprietary correction methods.

The multi-step process chain we have developed to manufacture aspherical optics is made of different milling processes as well as computer-controlled polishing processes. This process chain can be adapted as needed. This allows us to fulfill your individual requirements quickly and flexibly.

Processing aspherical components

Complete in-house processing chain

With us you get everything from a single source. We reproduce the entire processing chain in-house – the development, production, coating up to quality assurance and lens qualification. You profit from a high flexibility. Thus, your specific requirements can be fulfilled flexibly and rapidly.

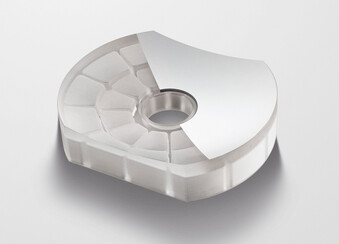

Light-weight structures

- Light-weight precision optics and components with the most modern CNC-controlled processing procedures

- Dimensional accuracy in the small nm range (despite lower wall thicknesses)

- After shaping: Stress-free etching of components in order to guarantee their long-term stability

5-axis grinding center

Aspherical mirror with light-weight structure

Contact our specialists

Please choose your contact partner:

Let us call you back!

SwissOptic AG

Heinrich-Wild-Strasse

9435 Heerbrugg, Switzerland

Phone +41 71 747-0420

swissoptic@swissoptic.com